Introduction:

Flexible bamboo plywood is gaining popularity in the construction and design industry due to its versatility and sustainability. These innovative materials offer a number of beneficial properties and are used in a wide variety of applications. In this blog, we will explore in detail the properties, applications and design variations of flexible bamboo plywood.

Properties of the plywood boards:

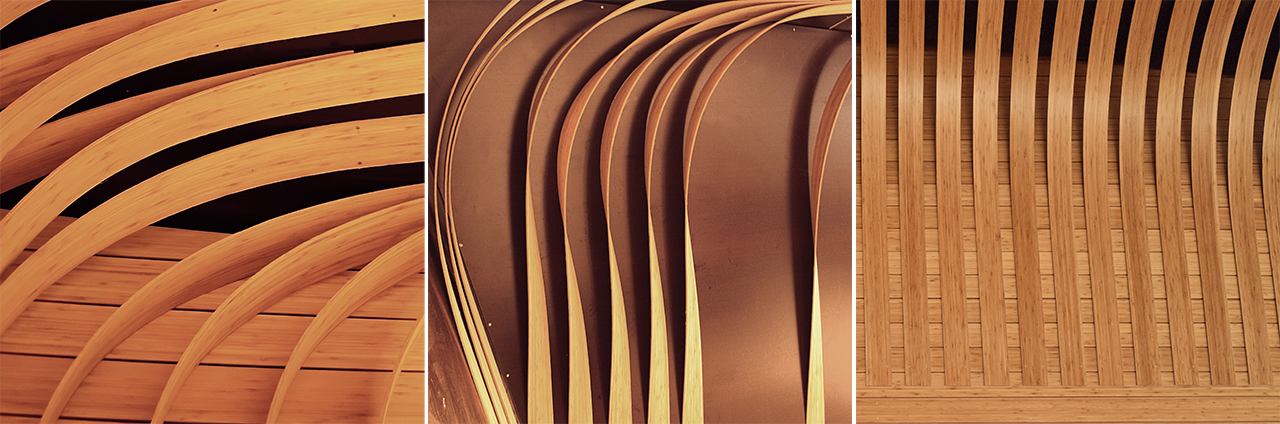

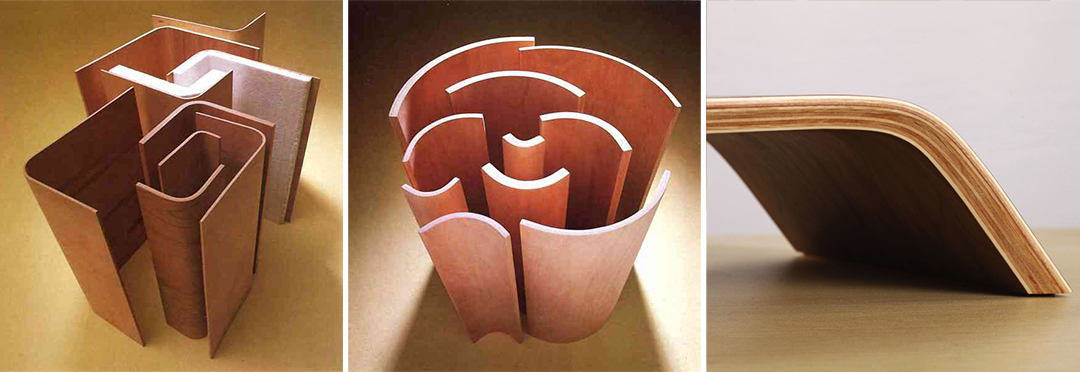

Bamboo plywood is known for its high strength and durability. Bamboo is a naturally resistant material that can withstand adverse conditions and mechanical stresses. One of the distinctive features of bamboo plywood is its flexibility. They can be easily bent and curved, which makes them ideal for applications requiring curved surfaces. By adding additives to the glue used in the manufacture we can obtain water-repellent _also called phenolic_, flame retardant, flexible boards…

Flexible bamboo plywood is less prone to warping and shrinkage than other materials due to its dimensional stability. This makes them suitable for environments with changes in humidity and temperature.

Water resistance: Flexible bamboo plywood panels are often designed to be water-resistant. This makes them suitable for applications in wet environments, such as kitchens, bathrooms or exteriors.

Environmental benefits: In terms of sustainability, bamboo is a fast-growing plant that is considered a sustainable alternative to traditional timber. Harvesting bamboo does not involve cutting down trees and its rapid regeneration makes it a renewable resource. In addition to being a sustainable option due to the renewable nature of bamboo, flexible plywood also has a low environmental impact during its production process. The adhesives used are often low in formaldehyde, which reduces emissions of harmful chemicals.

Insect and mold resistance: Bamboo naturally contains properties that make it resistant to insects and mold. Flexible bamboo plywood inherits these characteristics, making it a durable option that is resistant to biological degradation.

Manufacturing and applications

Flexible bamboo plywood is manufactured by bonding several thin layers of bamboo together using water and moisture resistant adhesives. These layers are arranged in alternating directions, which gives the board greater strength and stability. Depending on the use of the board, selected veneers are used for the top and bottom faces, and lower quality veneers can be used for the middle layers. In order to reach the desired board size, the existing veneers are sewn together.

Starting from the bottom veneer laid by the wire, other sheets are laid perpendicularly on top of the first one, previously glued on both sides by means of a roller machine. This process is carried out successively according to the desired thickness. Once they have all been joined together, the board is passed to a press which, depending on the glue applied, exerts pressure at a certain temperature to melt the different layers of bamboo.

Installation: Installation of these boards is similar to that of other plywood boards. They can be easily cut and shaped with common tools, and can be fastened with nails, screws or adhesives.

Maintenance: These boards are relatively easy to maintain. They can be cleaned with mild cleaning products and do not require intensive maintenance like traditional wood.

Certifications and standards: When choosing flexible bamboo plywood, it is advisable to look for products certified by recognised bodies that verify their sustainable origin and the quality of the adhesives used, such as the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI).

Different uses:

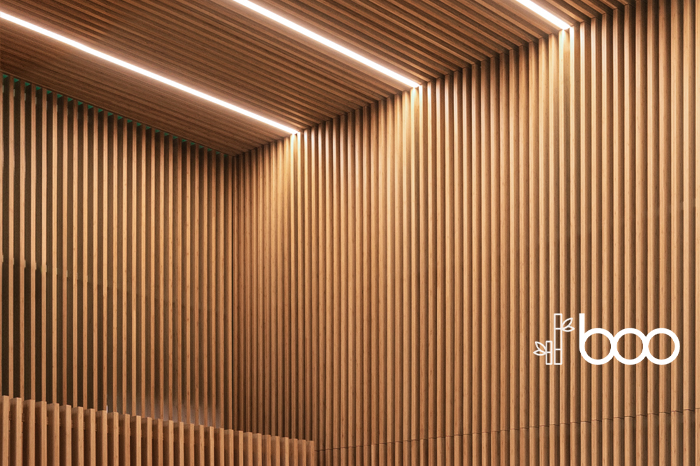

Architecture and interior design: These boards are widely used in the construction of curved structures and cladding, such as ceilings, walls and decorative elements. Their flexibility allows the creation of organic and customized shapes that add a unique aesthetic touch to interior spaces.

Furniture: Plywood is used in the manufacture of modern and sustainable furniture. Their ability to bend facilitates the creation of ergonomic and elegant designs. Due to their strength and flexibility, these boards are suitable for the manufacture of innovative container objects and packaging. They are used in the production of boxes and containers that require protection and structural strength.

Automotive sector: Flexible bamboo plywood also finds applications in the automotive industry. They are used in the interior cladding of vehicles to provide a natural and sustainable look, in addition to their durability and strength.

Design variations:

Finishes: One of the aesthetic aspects that impact within the design of plywood boards are their surface finishes. Plywood is available in a variety of finishes such as natural, charred or stained. Each option offers a unique look and feel, allowing for adaptation to different design styles.

Thickness and size: These boards can be found in different thicknesses and sizes to suit various applications. Some suppliers even offer the ability to customize sizes according to project requirements.

Combination with other materials: Plywood can be combined with other materials, such as glass or metal, to create innovative designs and interesting contrasts.

It is certainly an attractive option for those looking for a versatile, sustainable and durable material. Their unique properties, wide applications and design variations make them a popular choice in architecture, interior design, furniture, and other industries. By choosing these boards, you not only get a high-quality product, but you also contribute to preserving the environment. For more information, you can visit our section on our bamboo plywood planks here.